-

Description

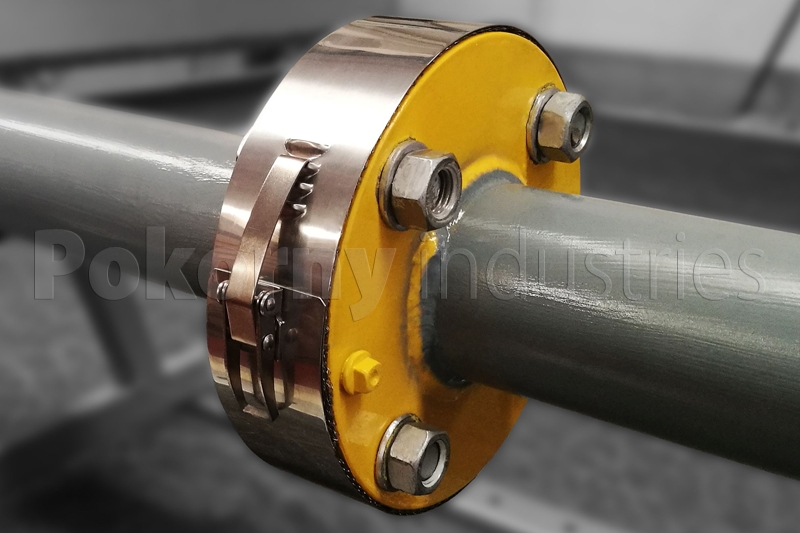

Leaking flange connections are a frequent cause of sudden and long outages. These leaks are usually caused by incorrect installation of flange joints, which results in uneven tightening even at the same tightening torque. The reason is improperly lubricated connecting material and its possible seizing.

POWER torque LF kote 450 is a heat-cured lubricant. It creates a dry, firmly anchored in the surface, sliding film with a long-term permanent lubricating effect even under extreme pressure loading. A thin greasy film permanently separates the individual materials from each other = prevents "biting" of surfaces into each other (for example screws and nuts). Especially suitable for stainless steel materials.

- Permanently anchored to the surface of the base material.

- Prevents "biting" of surfaces into each other.

- Minimizes the coefficient of friction.

- Minimal dispersion of tightening forces in the individual bolts ensures even compression of the seal.

- Even tightening ensures the tightness of the joint.

- Allows seamless enabling.

- Use from -70 ° C to +450 ° C.

- Extreme resistance to the pressure exerted on the threads of the bolts or on the washers during tightening.

- Completely eliminates errors when lubricating on site.

Resistance to compressive loads (in threads, under the nut head) - loads ASTM 2625 Method B> 250,000 psi (1,750 MPa).

Wear ASTM 2714 Method A> 300 minutes.Watch our explainer video

- Knowledge of the coefficient of friction is important for the actual calculation of the tightening torque and determination of the exact pressure on the seal.

- The constant coefficient of friction of all fasteners used ensures an even distribution of the pressure on the seal over the entire circumference of the sealing surface of the flange joint.

Lubricant application

The application of POWERtorque LF kote 450 dry lubricant to fasteners has its own technological procedure and requires special equipment. For this reason, the application cannot be carried out by the customer himself.

- We apply the fasteners supplied by us or you - screws, washers, nut faces.

- Can be applied to any base material - stainless steel, black steel, galvanized and more.

Friction coefficient test

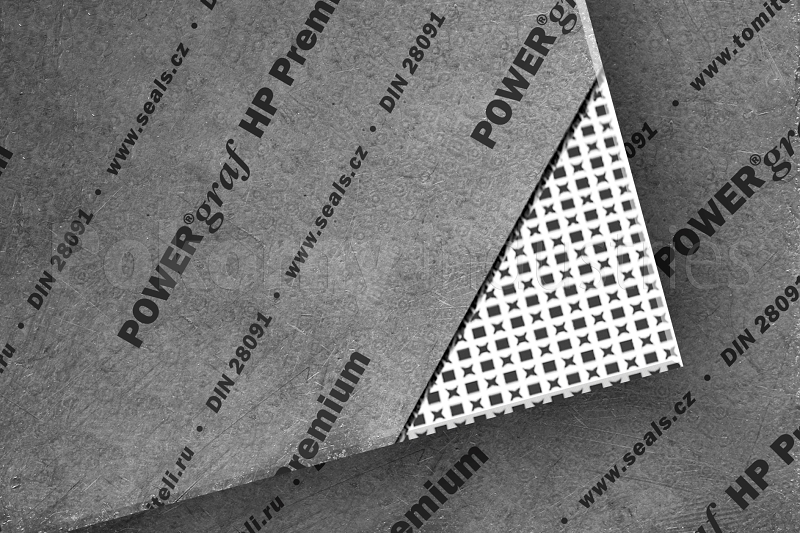

Tested according to ČSN EN ISO 16047, which stipulates the conditions for performing torque and clamping force tests for fasteners.

Nominal friction in the thread.

Nominal friction under the nut.

Powertorque LF Kote 450

POWER torque LF kote 450 is a heat-cured lubricant. Minimizes the coefficient of friction and prevents seizing.

.jpg)